Fust is the First Swiss Joinery to Use Powder Coatings on Wood

Joinery Fust AG ǀ Switzerland

The Fust joinery in the Swiss town of Wil has been synonymous with high-quality designer furniture, cabinet systems, doors, and kitchens for years. The surfaces of these wooden objects were previously veneered or coated with liquid varnish. The Wil-based carpenters and joiners now also rely on innovative powder coatings. With the support of IGP Pulvertechnik AG, also based in Wil, they have installed a new coating plant. And it did not take very long at all to get several new customers on board for IGP’s economical and ecological wood-coating process.

After three years of evaluation and planning, Fust AG recently commissioned its new powder coating plant. Owner Markus Fust is visibly pleased about this: “After producing various sample parts, we were finally able to go ahead with our first paid order. We were asked to manufacture and powder-coat a large number of cabinets for a business customer. We were all thrilled with the results.” Fust was particularly impressed by the excellent surface quality, which perfectly meets modern customer requirements. “Powder-coated surfaces are extremely robust, impervious to moisture, and easy to clean. They ensure that bathroom fixtures, kitchen furniture, and cabinets will still look like new after many years,” he adds. He and his customers were also impressed by the special anti-fingerprint properties and the soft silky feel of the coated surfaces.

Economical and eco-friendly

Alongside the durability associated with powder-coated furniture, the Fust team was also convinced by the cost-effectiveness of the process. Several work steps, such as filling and intermediate sanding, are completely eliminated, making the coating process extremely efficient. In addition, up to 90 percent of the overspray is recovered. IGP-RAPID® is also impressive in terms of its environmental performance – this powder coating consists entirely of solids and is therefore solvent-free. The components emit no harmful vapors, meaning that the product complies with the ECO-BKP standard. For the customer, this was another decisive argument in favor of this innovative process, which is in keeping with both the spirit of the times and the core values of the Swiss joinery.

Seamless all-round coating

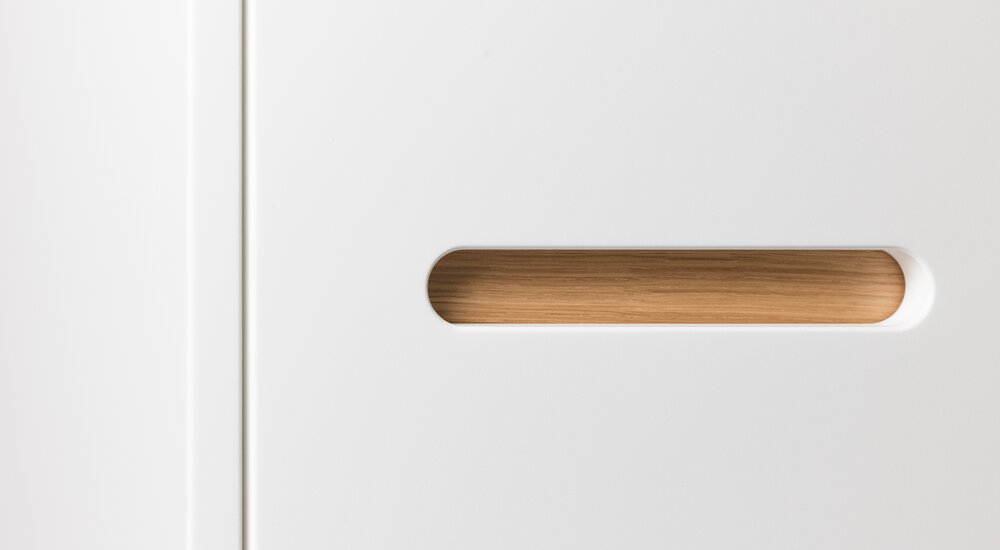

From the perspective of the Fust joinery sales team, the new process offers yet another advantage over alternative coatings for furniture: enormous freedom in terms of shapes and profiles. Thanks to all-round seamless coating, the powder coating also allows for sophisticated and complex geometries, such as milled angles, rounded corners, and finger holes. As a result, there are virtually no limits to design freedom with IGP-RAPID®.

A worthwhile investment

Although the Fust joinery has only recently started using powder coatings for wood, its management team is convinced that the investment has paid off: “It was clear to us from the start that we would need a lot of staying power if we were to build up this innovative technology. Ultimately, we want to move into new markets with powder coatings and also appeal to B2B customers with our new ‘FPP – Manufacturing Partner for Wood Professionals’ business segment.” The management team expects the powder coating plant to reach break-even in 24 to 36 months.