How a Belgian Kitchen Furniture Manufacturer Became a Pioneer in Powder-Coated MDF

Kempa products nv ǀ Belgium

Kempa Products NV, a Belgian manufacturer of high-quality kitchen furniture and interior furnishings, was among the first companies to use powder coatings on MDF at its 1,800 m2 production facility and has been collaborating with IGP Powder Coatings in this area for some time. The pioneering work has paid off. Thanks to this innovative process, Kempa can now offer furniture with a much more durable and ecological surface finish via a coating process that is also many times faster.

“Together with IGP Powder Coatings, we were the pioneers of powder-coated MDF. Today, we work together to continuously develop the process. In the future, we will be able to use powder coatings on materials that are unthinkable today. We are absolutely sure of that. Our current tests indicate huge potential in this area.”

Statement by Paul Maeyninckx, owner and CEO of Kempa

Ten times faster

When Kempa’s owner Paul Maeyninckx took the decision to start powder coating his products, he was certainly expecting to see an increase in the speed of the processes. What surprised him, however, was that this innovative process managed to unlock a tenfold increase in production output. “It depends on the substrate and the number of coats, of course,” says Maeyninckx, “but with IGP-RAPID® it takes just three minutes to dry through, compared to up to half an hour in the case of liquid coatings.” In addition to shorter drying times, powder coatings also eliminate the need for repeated sanding and over-coating. Thanks to the high degree of automation, the reduction in the length of the process as a whole is truly impressive.

Durability and quality

However, the new process did not just win Kempa over by saving them time and, in turn, gain efficiency. Powder-coated surfaces are more scratch-proof and moisture resistant than liquid-coated ones. “A vital factor for us is that the visual quality must match that of the liquid-coated elements. And it does so fully,” says Maeyninckx. “Customer feedback repeatedly confirms that this process is not only less expensive, but also improves the quality of the surfaces. The color fastness is tremendous and yellowing of kitchen furniture is no longer an issue,” he adds.

Ecological and sustainable

IGP-RAPID® is also impressive in terms of its carbon footprint. According to Kempa this has become increasingly important, especially for architects, since powder-coated interiors give them great advantages when bidding for contracts for municipal buildings. These days, local authorities give priority to ecological construction methods – in some cases, they actually insist on it. IGP powder coatings consist entirely of solids and are therefore solvent-free. The components emit no harmful vapors, meaning that the products comply with the ECO-BKP standard. In addition, up to 90 percent of the excess powder can be recovered – and thanks to the faster coating processes, energy consumption is significantly reduced compared to the conventional liquid coating process.

Design freedom

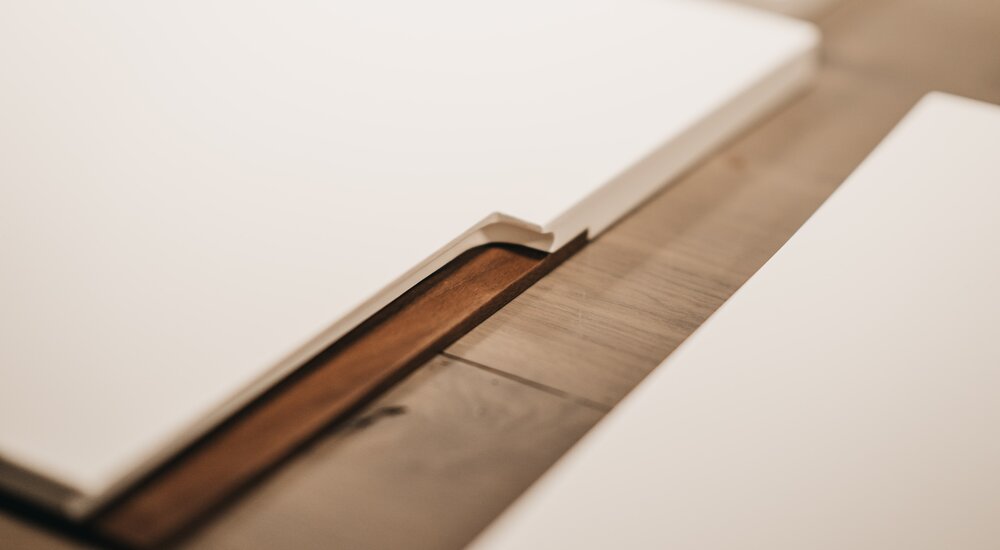

Powder coatings can be used to coat combinations of different materials. This all-round, seamless coating method also allows for sophisticated and complex geometries, such as milled angles, rounded corners, and handles. The powder coating is electrostatically charged to ensure that every part of the substrate is covered with powder. During curing, the powder layer forms a closed and seamless coating layer.